They were synthesized with different compositions and produced by various processing routes. From these “new” elements, numerous metallic materials including engineering and advanced alloys have been developed. When the first industrial revolution began in later half of 18th century in England, more and more elements were found and produced by humankind.

Universities Press (India), Hyderabad, India. Indian’s Legendary Wootz Steel-An Advanced Material of the Ancient World. From Srinivasan, S., Ranganathan, S., 2014. The material hypertetrahedron for wootz steel. It can be regarded as a classic example of the material tetrahedron but including a fifth vertex of modeling (e.g., CALculation of PHAse Diagrams (CALPHAD) method to calculate phase diagram) to make it a hypertetrahedron.įig. The facets of the ultrahigh-carbon steels, Buchanan furnace, the Fe-C phase diagram, the microstructure of dendrites in the as-cast state and spheroidized cementite in the forged state, the superplastic elongation, and the damascene marks are emphasized for the strong interconnections among them. 1.3 shows that materials hypertetrahedron that links the above four with modeling is necessary to understand the performance of wootz steel ( Ranganathan and Srinivasan, 2006 Srinivasan and Ranganathan, 2014). The deciphering of wootz steel by European scientists led to the correlation between structure and properties at first and subsequently between composition, processing, structure, and properties. This has been rightly celebrated as the most advanced material of the ancient world, as this steel was used to fashion the Damascus swords.

This accidental discovery also led to the production of wootz steel in India around 300 BCE. This is all the more astonishing as carbon was not recognized as an element until recently. Steel was an accidental alloy of iron with carbon. Wrought iron was produced as early as 1000 BCE, and cast iron and cast steel were produced one millennium later. Zinc was added in the 12th century to form silvery and rust-resisting alloy known as paktong (white copper), which was widely used in Europe before stainless steel was invented. When the sulfide ores of copper and nickel were smelted together, it led to copper-nickel alloy in the fourth century in China. This is an early application of an intermetallic. Archaeometallurgical investigations by Sharada Srinivasan on vessels from South Indian megaliths of the Nilgiris and Adichanallur (1000–500 BCE) showed that they were of wrought and quenched high-tin beta bronze, ranking among the earliest known artifacts. Mirrors were made of bronzes in different parts of the Old World including India and China, due to their higher hardness, which makes it easy in getting mirror finish to reflect like silver. It is interesting to mention that intermetallics of copper-tin alloys had been used in ancient time. The eighth metal, zinc, is added not only because of the unique Indian context but also because the discovery of other metals had to await the advent of the scientific revolution for a few centuries. The seven metals found in antiquity were gold, copper, silver, iron, lead, tin, and mercury.

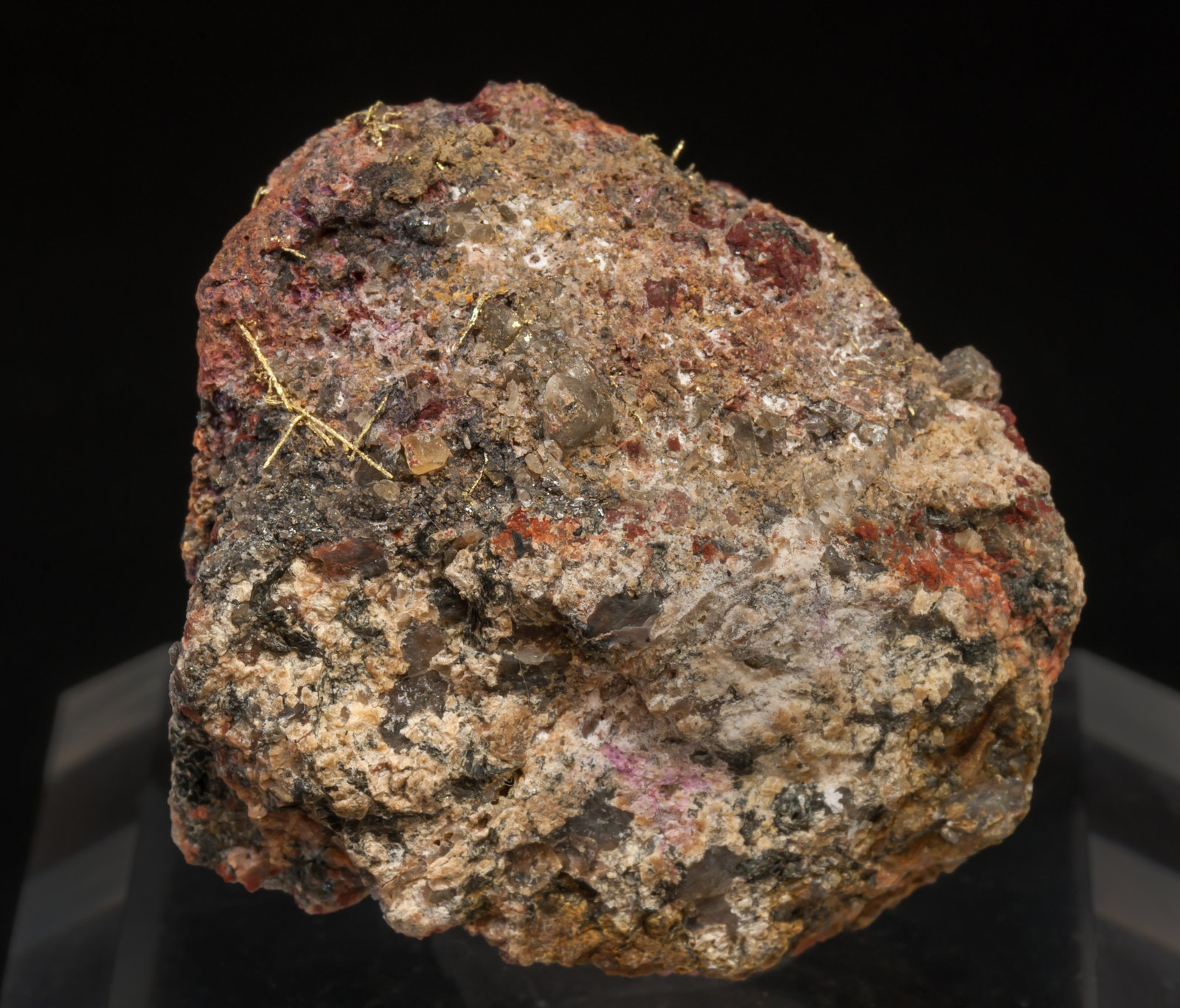

A more intentional alloying of tin with copper (tin bronzes in 2500 BCE) gave birth to the Bronze Age, as bronze was superior in its mechanical properties. The first alloy of copper and arsenic (arsenical bronze, 3000 BCE) was entirely accidental. In the primitive fires in the caves, ores of copper got mixed with ores of arsenic, zinc, and tin. It is an early example of multicomponent high-entropy alloys (HEAs), since platinum is often found as alloys with the other platinum group metals and iron mostly.Īlloying was an accidental discovery. Also, mixtures of platinum metals are found to occur in nature. When platinum was discovered in 1735, it was compared with silver. Native alloys such as tumbaga and electrum are alloys of gold-copper and gold-silver, respectively. Bhattacharjee, in High-Entropy Alloys (Second Edition), 2019 1.2 The coming of alloys

0 kommentar(er)

0 kommentar(er)